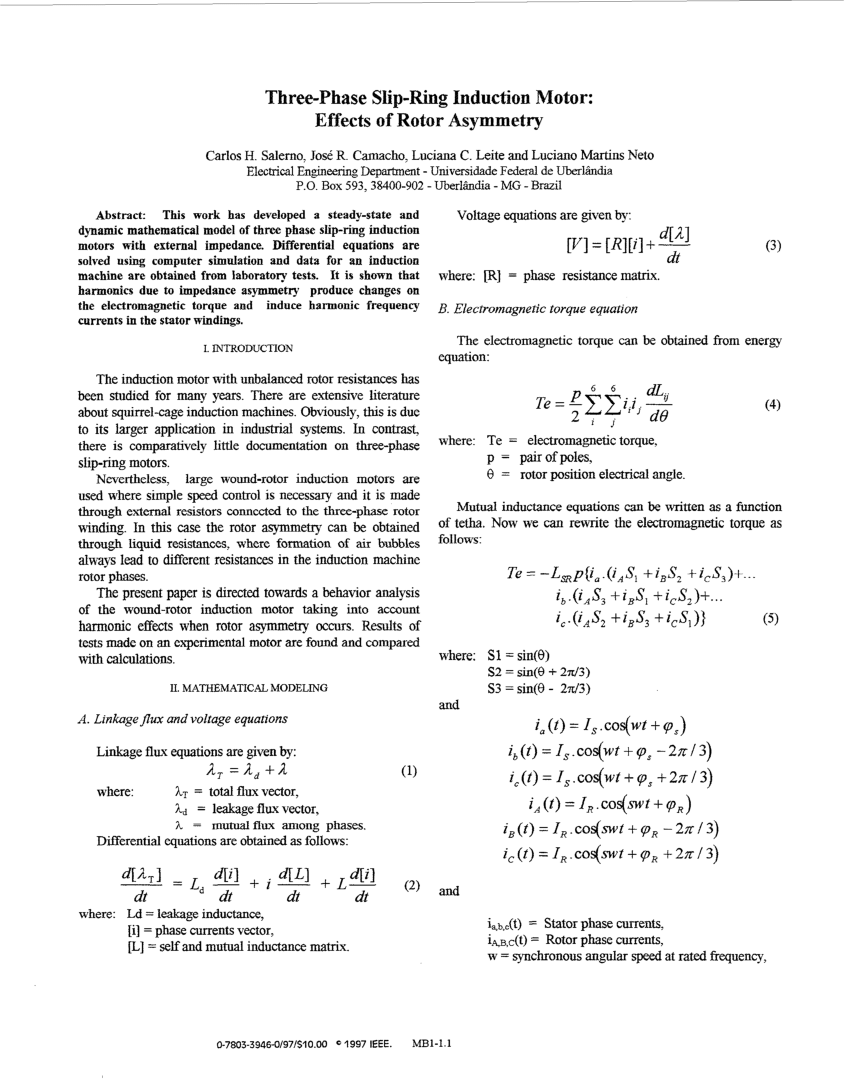

A wound rotor motor also known as slip ring rotor motor is a type of induction motor where the rotor windings are connected through slip rings to external resistance.

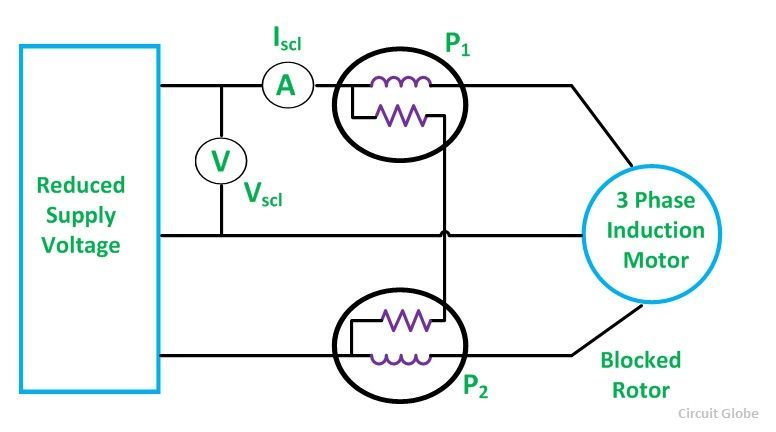

Slip ring induction motor rotor current.

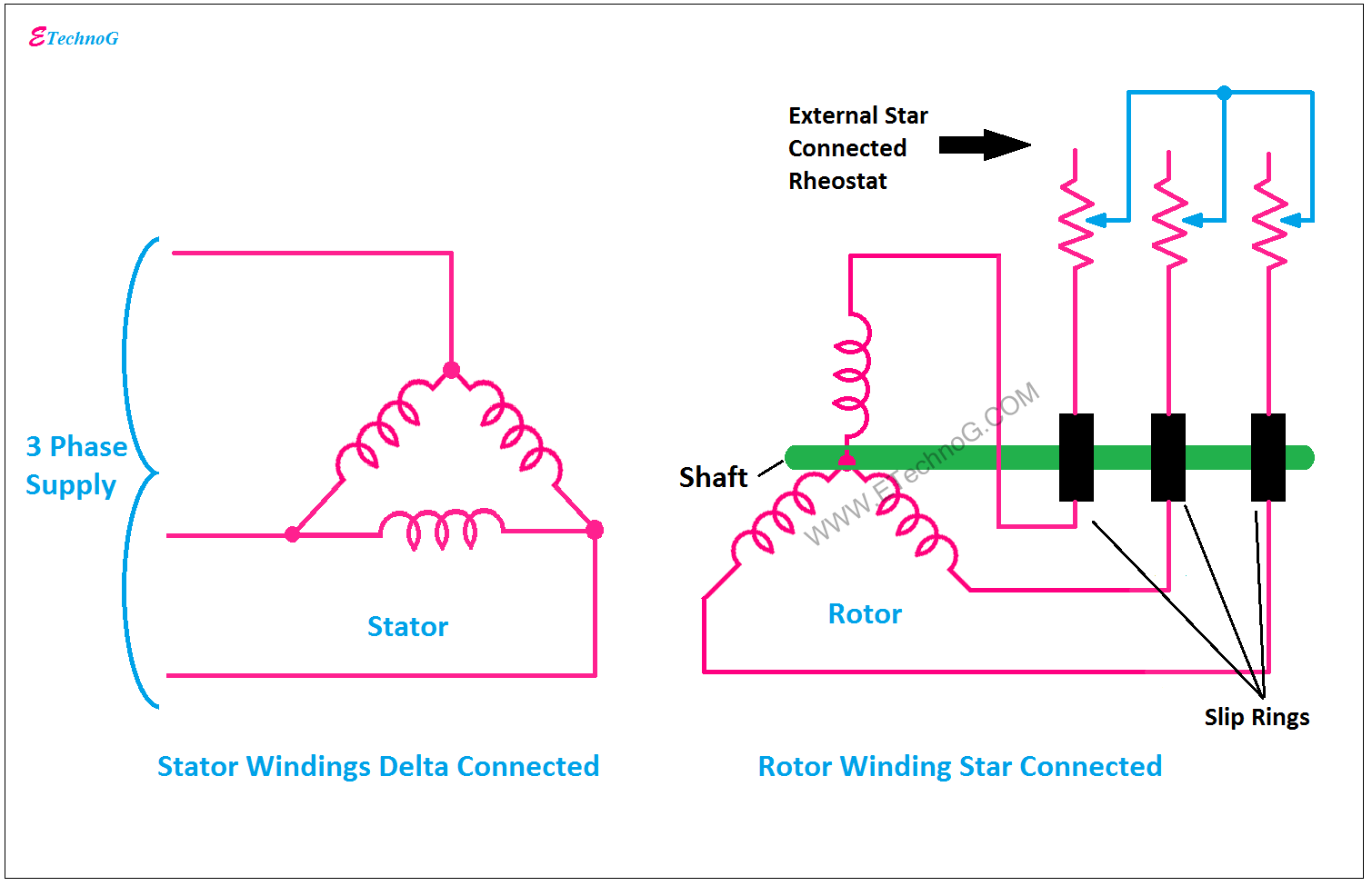

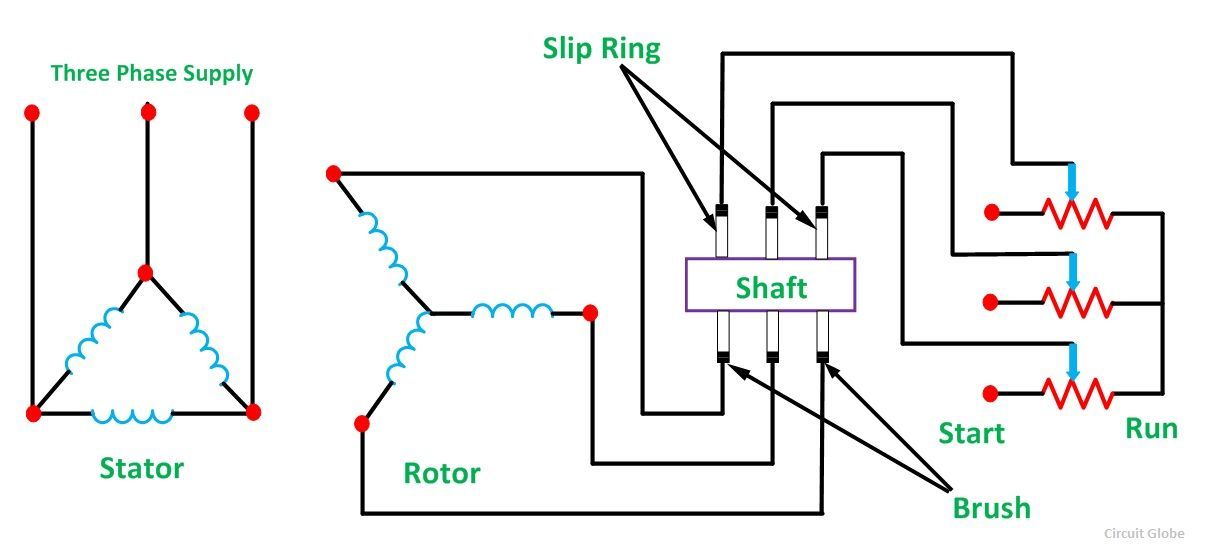

The slip ring induction motor has two distinctly separate parts one is the stator and other is the rotor.

A wound rotor motor uses three slip rings typically made of copper or a copper alloy mounted to but insulated from the motor shaft.

The rotor winding is distributed as well short pitched to get a sinusoidal emf output.

Slip ring induction motor is one of the types of 3 phase induction motor and is a wound rotor motor type.

It consists laminated cylindrical core which has a semi closed slot at the outer periphery and carries three phase insulated winding.

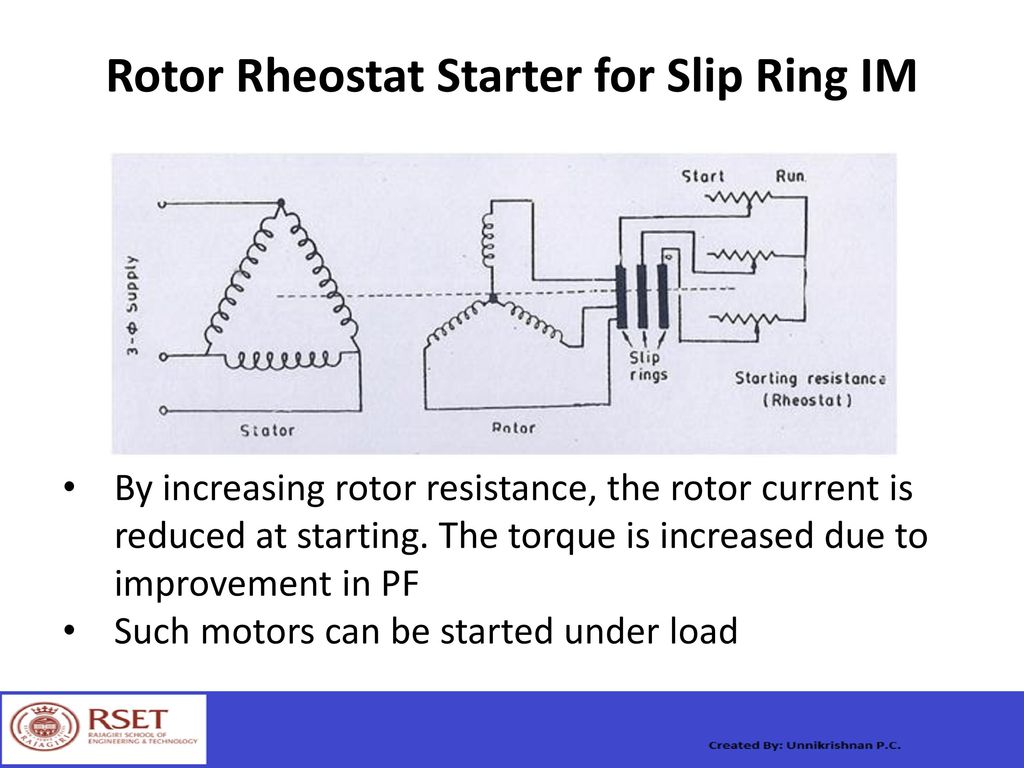

As a slip ring induction motor starts the external resistance value is increased fig 11.

It is controlled by varying the rotor current of the motor.

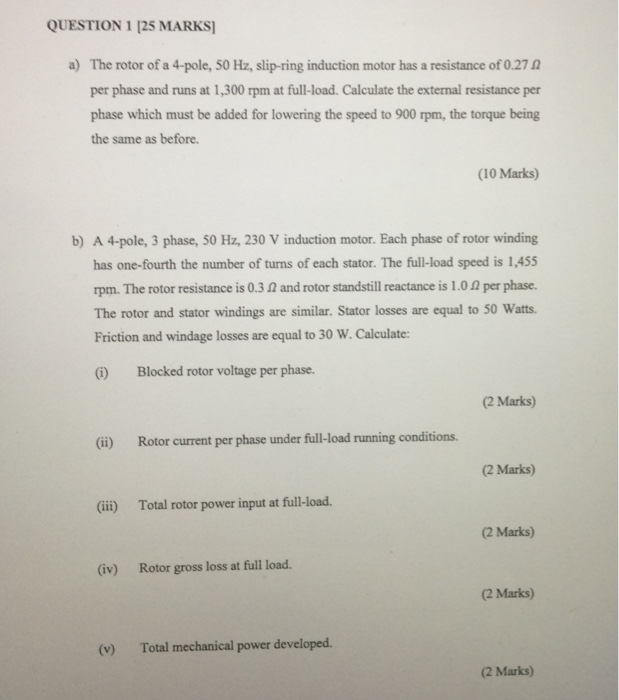

Adjusting the resistance allows control of the speed torque characteristic of the motor.

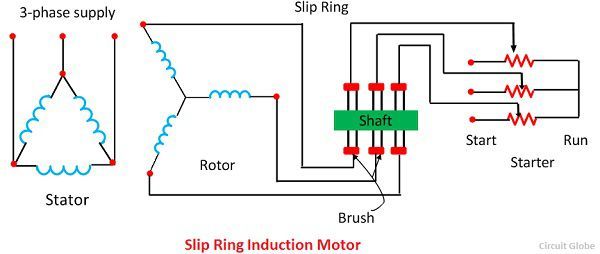

The function of a three phase slip ring induction motor is shown in the figure below.

In a version of the ac induction motor referred to as a wound rotor motor slip rings are used not for transferring power but for inserting resistance into the rotor windings.

To achieve this the rotor ac current is converted by means of a three phase.

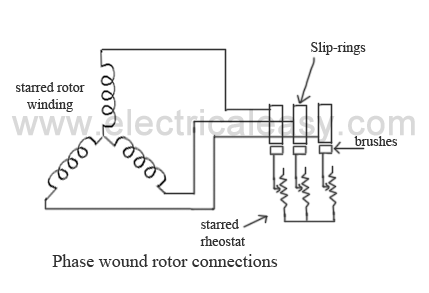

The motor which employing the wound rotor is known as a slip ring induction motor or phase wound motor.

Slip rings i m provides some advantages like provides high starting torque low starting current and it improves the power factor.

Definition of slip ring motor.

Their sole purpose is to allow resistance to be placed in series with the rotor windings while starting figure below.

A wound rotor induction motor has a stator like a squirrel cage induction motor but a rotor with insulated windings brought out via slip rings and brushes.

This reduces the phase difference angle and the current induced approaches the maximum torque condition.

As rotor current is directly proportional to the speed and torque of three phase ring type.

Because of various advantages like low initial current high starting torque and improved power factor it is used in applications that require high torque cranes and elevators.

Wound type rotor or slip ring type rotor this type of rotor is also made up of laminated cold rolled grain oriented silicon steel to reduce eddy current loss and hysteresis loss.

However no power is applied to the slip rings.